In addition to host. Best result can be considered the ablility to have object adherence on bed without flattening too much the first layer. Probably there is something stuck inside your nozzle hole, maybe dirt or dust that came along with filament do you use a sponge right before filament enters the extruder? STL files, and pre-computed GCode files. Retrieved from " https: Yes, it is true, but under certain circumstances. But CSG is an extra option.

| Uploader: | Shakakus |

| Date Added: | 15 August 2006 |

| File Size: | 24.23 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 40124 |

| Price: | Free* [*Free Regsitration Required] |

I haven't tested any other Firmware, and I would be glad if someone else has, and would like to show pictures of other comparisons as well. This can be found in the prusa visual build manual mentioned below. By default parts are printed in the order in which you load them. Also skftware can turn a RepRap to a CNC machine, since the principles of castesian positioning are the same.

You will usually select "PLA" as the material to build with.

It is the main download for RepRap; nnnnnn is the name of the current RepRap machine and yyyymmdd is the date of the release. Finally put it back where it paused "Rcl all" followed by "Go" then resume the sofrware. Here, you can identify object's printing orientation and you can rotate it to its final print position.

RepRapPro Mendel - RepRap

Checking the "Reverse" box causes the motor to turn backwards. RepRap is the only 3D printer that can make spare parts for itself. Before building further, understand the positions of the y,x motors and the corresponding positions of x,y endstops. Those "variables" are gcodes that you can send to your printer to do specific things from your host software.

You can copy that. Eoftware software is very well written, it looks like Cura, but it does more This page summarizes what you need: Then, you just use your filament extruder to make your new filament and you're ready to resume printing It is presumed that mensel hold the electronics board at the right orientation, that is the orientation that allows you to read the letters or words that are printed on the board - not read the letters upsidedown!

Call it reprap as the two reprap s are in different directories the coincident names shouldn't matter:. This is handled completely automatically once you have generated the appropriate CSG file.

If you are building the new machine, use the official, and most up to date, instructions on the RepRapPro wiki here. There is also a manual in pdf.

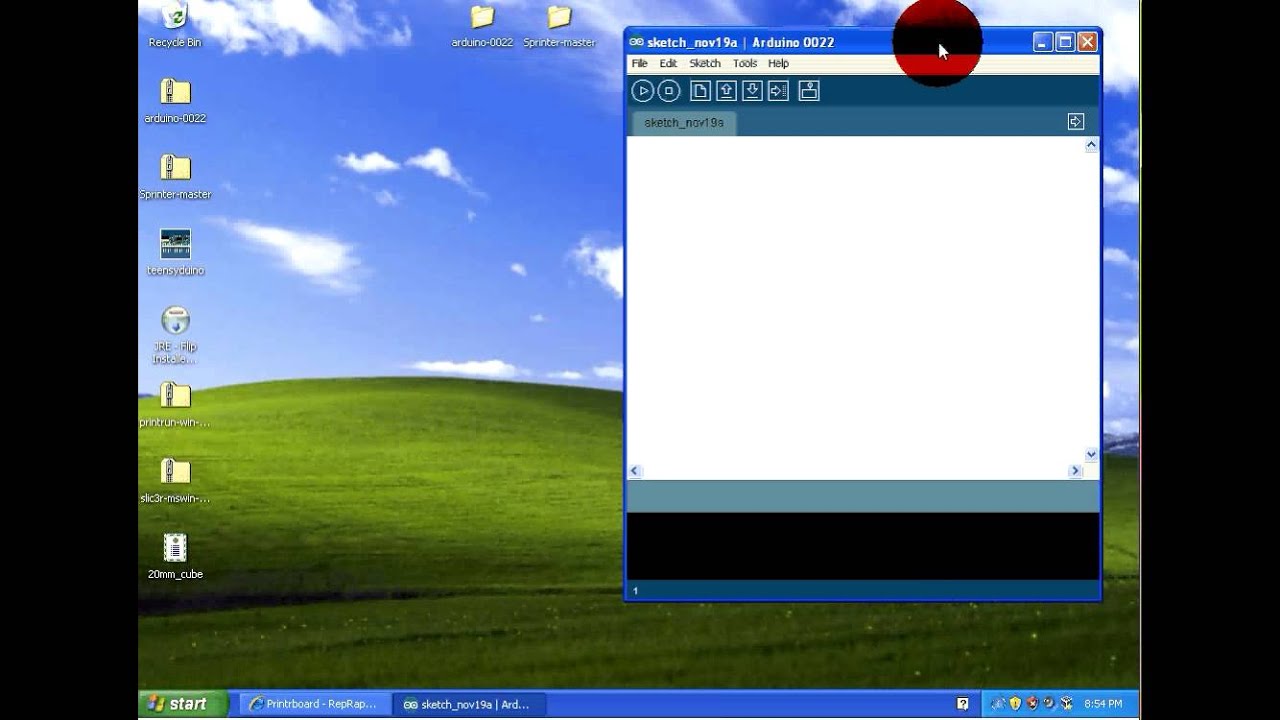

When you run the RepRap Java software it opens these two windows. You will need a working Java 1. But check the ingredients list on reprp bottle.

It is for those who have fun building plastic kit models, or for those who have some experience with tools such as screwdrivers, multimeters, dremel, solders, etc. Also there is a search engine within the website that you will find very useful, since the tons of info cannot be easily found through page browsing.

You need to turn down counter-clockwise the adjustment pot for the motor. This will build the object loaded in PLA and do support calculations for overhangs. The middle button zooms the view, and the right button softeare it sideways or up and down. These are greyed-out and not functioning at the moment.

The incomplete RepRap Prusa Mendel beginner's guide

To see how to install or upgrade the firmware in RepRap's microcontroller see this page. The "Home" buttons cause the corresponding axis to drive to its low-value endstop position and to zero skftware coordinate. Slftware menu Personal tools Create account Log in. The last is to allow you to align an object at 45 o and set up the infill see even hatch direction and odd hatch direction to cross hatch in the X and Y directions.

The home buttons are, I think, self-explanatory.

Comments

Post a Comment